If you’ve ever operated a tractor with a pickup hitch, there is a strong possibility it was manufactured in Dromone Engineering.

An average of 200 quick couplers and 140 quick hitches leave the company’s factory in the village of Dromone outside Oldcastle, Co Meath, each week. Dromone Engineering currently employs 150 full-time staff.

The business

Dromone native Patrick McCormick set up Dromone Engineering after developing a pickup hitch to suit the popular Ford and Massey Ferguson tractors of the era.

His pickup hitch was a major step forward for farmers coming from a traditional drawbar system, reducing time and effort when changing machinery.

Patrick switched his focus to the design and manufacture of the Dromone pickup hitch as well as continuing to raise awareness by attending the annual Spring Show.

Each pickup hitch is boxed individually with its necessary components for fitment.

In the late 1980s and early 1990s, Dromone secured a contract to supply pickup hitches to Renault Agriculture. So, Dromone pickup hitches were fitted to tractors built in the Le Mans factory in France that were destined for UK and Irish markets, and some Scandinavian countries. Shortly after, a deal was done to supply hitches to Case IH.

Meanwhile, development of the product was continuing. In 1991, Dromone Engineering launched the first hydraulic push-back hitch, providing greater visibility to the operator of the hook and trailer’s ring from the cab.

A batch of pickup hitches after being welded before sand blasting and painting.

The small product range meant the company needed a high-volume market. Over the next few years, contracts were signed to supply hitches to John Deere in Mannheim and Massey Ferguson in Coventry.

At this stage, sales to manufacturers accounted for almost all of the business, with production at its maximum. However, having such a focused product offering and few very large-scale customers brought its own challenges. Holding on to contracts was necessary to survive.

Turning point

Current managing director William Egenton joined the team in 2002, which was a tough period for the company with the loss of some contracts due to the merging of the CNH group, which later resulted in the sale of the Case IH factory in Doncaster. This prompted Dromone Engineering to diversify and establish new markets.

Shortly after, the company introduced a new product offering that would complement the tractor pickup hitch range, this being an excavator quick coupler. The quick coupler suited Dromone’s portfolio well, providing the security of not having to solely rely on one market. Today, construction products account for half of the company’s annual turnover.

His pickup hitch was a major step forward for farmers coming from a traditional drawbar system, reducing time and effort when changing machinery

To this day, Dromone’s core products remain the same. Business improved throughout the 2000s with the launch of its excavator quick couplers in North American and European markets.

The Dromone ball and spoon coupling system followed, which is today becoming increasingly popular given its ability to legally carry greater load while creating less movement and wear compared to the standard hook and eye system.

Dromone Engineering Ball and Spoon coupling.

On the construction side, the Multi-Lock quick coupler entered the market which allowed operators to change attachments without leaving the driver’s seat. Not a company to sit still, Dromone then launched its linkless roller pickup hitch.

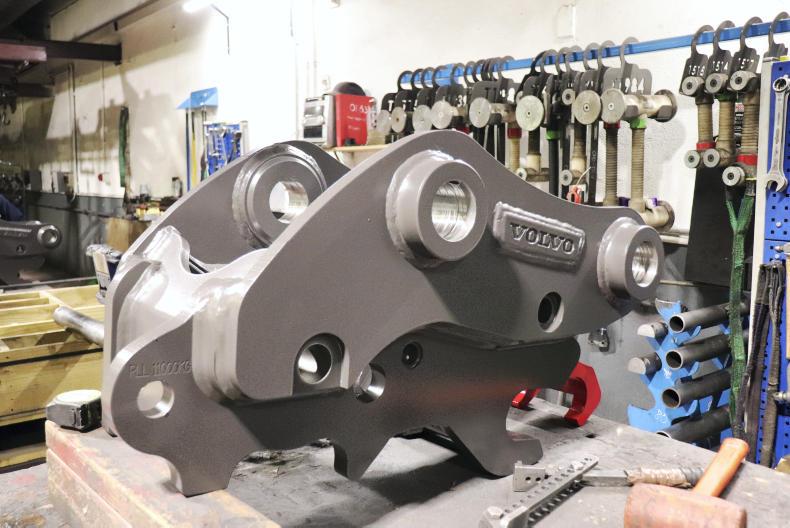

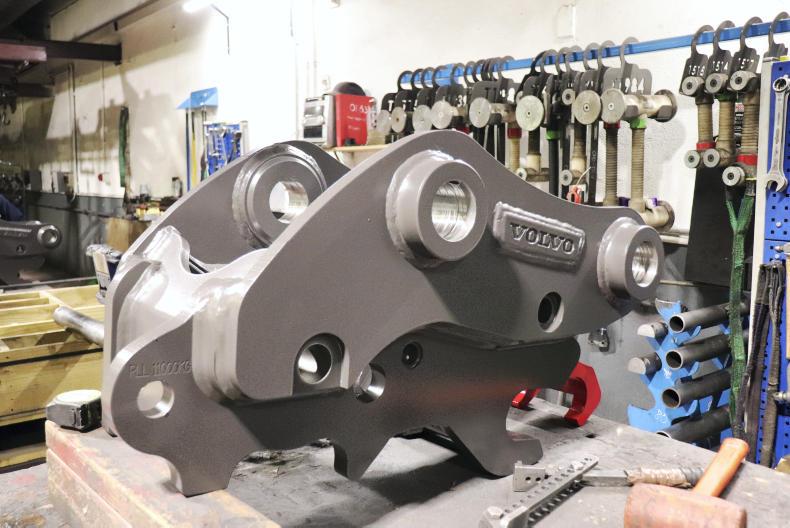

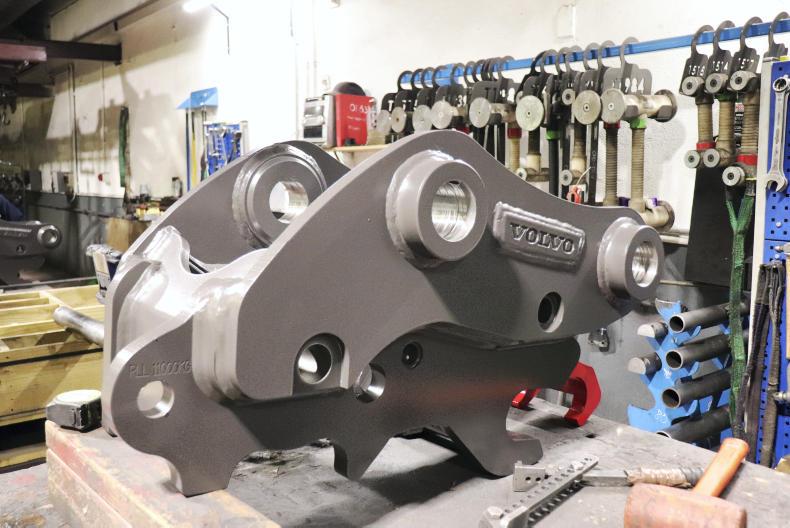

Dromone Multi Lock Coupler during assembled.

Dromone today

Today, export markets account for almost 100% of the business, to 39 countries. Currently Dromone supplies pickup hitches to Kubota, AGCO, SDF, Claas and ARGO tractors. Its products are also sold to customers through distributor dealer networks. Fastparts is the Irish distributor and Lynx Engineering takes care of distribution throughout the UK.

On the excavator side of the business, Dromone supplies Volvo and a large rental business based in North America.

William explained that the agricultural market differs from the construction market whereby tractor manufacturers fit different hitch systems on tractors depending on the country of sale.

All necessary components to assemble each order are put into divided boxes to speed up the assembly process.

In countries such as Germany and France, tractors are equipped with ladder-type hitches, whereas in Ireland, the UK and some Scandinavian countries pickup hitches are standard.

The construction industry is different in that all excavators use the same hitch type all over the world.

Dromone Engineering has not stood still from an engineering perspective. In 2000, the design team consisted of one engineer and one draftsman. Today, this number is in the high 20s.

Today, export markets account for almost 100% of the business, to 39 countries

Just over five years ago, the company implemented lean manufacturing, which according to William has been a huge success in guaranteeing consistent quality, utilisation of factory space and the overall reduction in downtime.

As a result of being at the very forefront of modern manufacturing, the company has won awards at a national level. Testament to this is the company’s more recent adoption of Industry 4.0, which is an ongoing project to achieve the very latest standards in modern manufacturing.

One principals of Lean manufacturing is that every tool has a place, this is to eliminate time wasting looking for tools.

Future

William believes the market has a growing appetite for smart systems and that this is where the future lies. As a result, this is an area the R&D department is constantly exploring.

The recent launch of the Hitched and Locked (HAL) pickup hitch is a clear indication of the company’s direction.

The new Hitched & Locked system (HAL) launched at Lamma show this year.

This is where sensors and a human interface work together to eliminate the possibility of error and make the process safer. William feels this is where Dromone Engineering will succeed given the strength of its engineering team and mindset to embrace automation and the latest technologies.

Business: Dromone Engineering.Established: 1978 by Patrick McCormick. Managing director: William Egenton. No. of employees: 150.Address: Dromone, Oldcastle, Co Meath.Main products: Pickup hitches and excavator quick hitches.Export markets: 39 countries.

If you’ve ever operated a tractor with a pickup hitch, there is a strong possibility it was manufactured in Dromone Engineering.

An average of 200 quick couplers and 140 quick hitches leave the company’s factory in the village of Dromone outside Oldcastle, Co Meath, each week. Dromone Engineering currently employs 150 full-time staff.

The business

Dromone native Patrick McCormick set up Dromone Engineering after developing a pickup hitch to suit the popular Ford and Massey Ferguson tractors of the era.

His pickup hitch was a major step forward for farmers coming from a traditional drawbar system, reducing time and effort when changing machinery.

Patrick switched his focus to the design and manufacture of the Dromone pickup hitch as well as continuing to raise awareness by attending the annual Spring Show.

Each pickup hitch is boxed individually with its necessary components for fitment.

In the late 1980s and early 1990s, Dromone secured a contract to supply pickup hitches to Renault Agriculture. So, Dromone pickup hitches were fitted to tractors built in the Le Mans factory in France that were destined for UK and Irish markets, and some Scandinavian countries. Shortly after, a deal was done to supply hitches to Case IH.

Meanwhile, development of the product was continuing. In 1991, Dromone Engineering launched the first hydraulic push-back hitch, providing greater visibility to the operator of the hook and trailer’s ring from the cab.

A batch of pickup hitches after being welded before sand blasting and painting.

The small product range meant the company needed a high-volume market. Over the next few years, contracts were signed to supply hitches to John Deere in Mannheim and Massey Ferguson in Coventry.

At this stage, sales to manufacturers accounted for almost all of the business, with production at its maximum. However, having such a focused product offering and few very large-scale customers brought its own challenges. Holding on to contracts was necessary to survive.

Turning point

Current managing director William Egenton joined the team in 2002, which was a tough period for the company with the loss of some contracts due to the merging of the CNH group, which later resulted in the sale of the Case IH factory in Doncaster. This prompted Dromone Engineering to diversify and establish new markets.

Shortly after, the company introduced a new product offering that would complement the tractor pickup hitch range, this being an excavator quick coupler. The quick coupler suited Dromone’s portfolio well, providing the security of not having to solely rely on one market. Today, construction products account for half of the company’s annual turnover.

His pickup hitch was a major step forward for farmers coming from a traditional drawbar system, reducing time and effort when changing machinery

To this day, Dromone’s core products remain the same. Business improved throughout the 2000s with the launch of its excavator quick couplers in North American and European markets.

The Dromone ball and spoon coupling system followed, which is today becoming increasingly popular given its ability to legally carry greater load while creating less movement and wear compared to the standard hook and eye system.

Dromone Engineering Ball and Spoon coupling.

On the construction side, the Multi-Lock quick coupler entered the market which allowed operators to change attachments without leaving the driver’s seat. Not a company to sit still, Dromone then launched its linkless roller pickup hitch.

Dromone Multi Lock Coupler during assembled.

Dromone today

Today, export markets account for almost 100% of the business, to 39 countries. Currently Dromone supplies pickup hitches to Kubota, AGCO, SDF, Claas and ARGO tractors. Its products are also sold to customers through distributor dealer networks. Fastparts is the Irish distributor and Lynx Engineering takes care of distribution throughout the UK.

On the excavator side of the business, Dromone supplies Volvo and a large rental business based in North America.

William explained that the agricultural market differs from the construction market whereby tractor manufacturers fit different hitch systems on tractors depending on the country of sale.

All necessary components to assemble each order are put into divided boxes to speed up the assembly process.

In countries such as Germany and France, tractors are equipped with ladder-type hitches, whereas in Ireland, the UK and some Scandinavian countries pickup hitches are standard.

The construction industry is different in that all excavators use the same hitch type all over the world.

Dromone Engineering has not stood still from an engineering perspective. In 2000, the design team consisted of one engineer and one draftsman. Today, this number is in the high 20s.

Today, export markets account for almost 100% of the business, to 39 countries

Just over five years ago, the company implemented lean manufacturing, which according to William has been a huge success in guaranteeing consistent quality, utilisation of factory space and the overall reduction in downtime.

As a result of being at the very forefront of modern manufacturing, the company has won awards at a national level. Testament to this is the company’s more recent adoption of Industry 4.0, which is an ongoing project to achieve the very latest standards in modern manufacturing.

One principals of Lean manufacturing is that every tool has a place, this is to eliminate time wasting looking for tools.

Future

William believes the market has a growing appetite for smart systems and that this is where the future lies. As a result, this is an area the R&D department is constantly exploring.

The recent launch of the Hitched and Locked (HAL) pickup hitch is a clear indication of the company’s direction.

The new Hitched & Locked system (HAL) launched at Lamma show this year.

This is where sensors and a human interface work together to eliminate the possibility of error and make the process safer. William feels this is where Dromone Engineering will succeed given the strength of its engineering team and mindset to embrace automation and the latest technologies.

Business: Dromone Engineering.Established: 1978 by Patrick McCormick. Managing director: William Egenton. No. of employees: 150.Address: Dromone, Oldcastle, Co Meath.Main products: Pickup hitches and excavator quick hitches.Export markets: 39 countries.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: