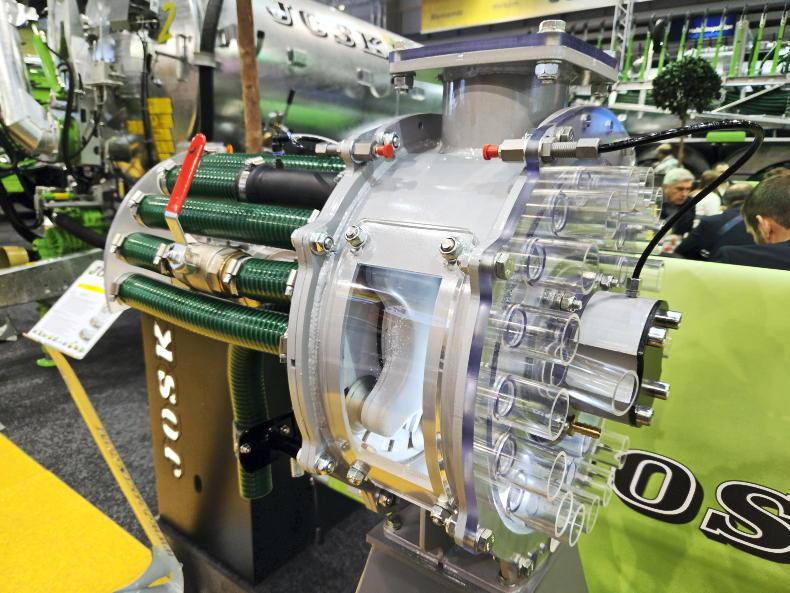

Joskin has just taken the wraps off its latest Scalper macerator.

According to the Belgian manufacturer, the new version provides greater precision and versatility and can now be fitted to a wider range of implements in its range.

Joskin first patented the Scalper macerator in 1991.

It says it’s designed to work with cattle slurry, which is often obviously loaded with fibres and foreign bodies, that can cause irregularities in spreading and clog pipes.

How does it work?

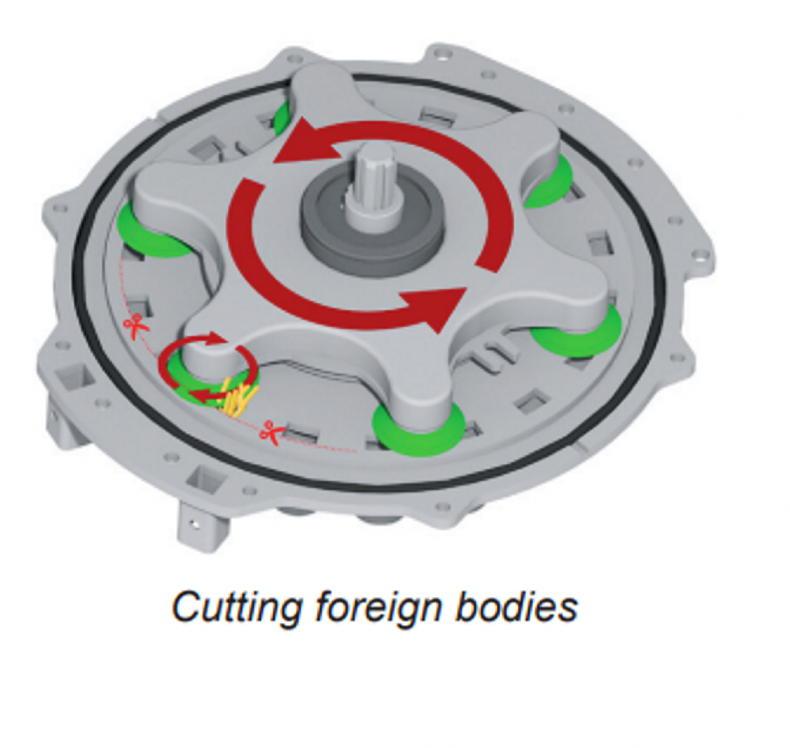

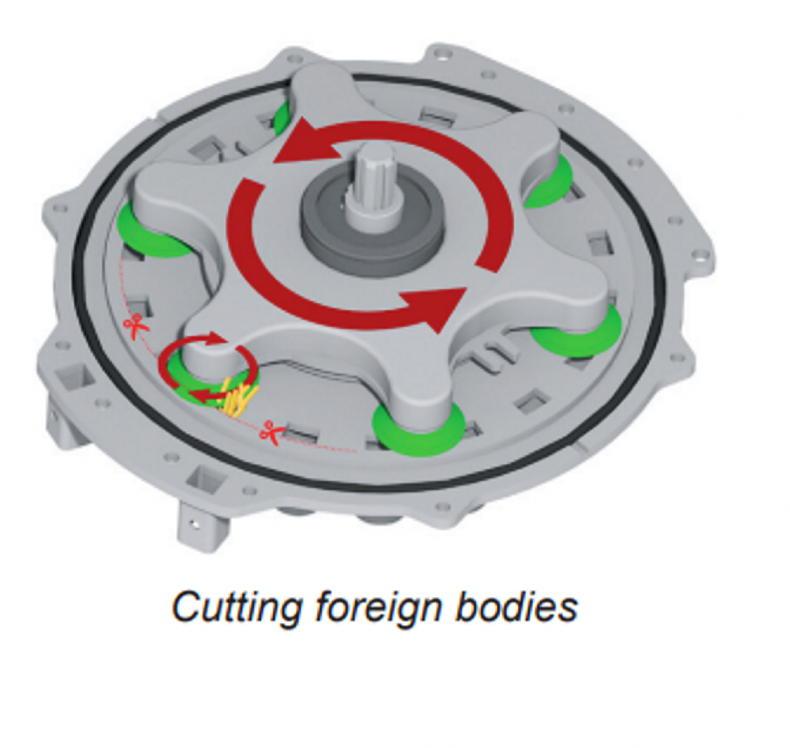

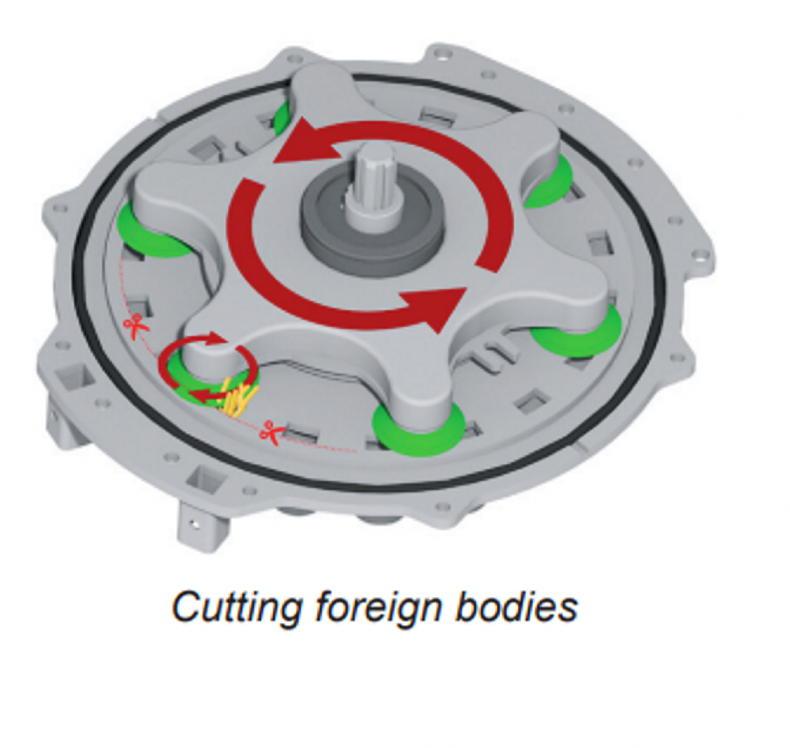

Interestingly, Joskin claims that it was the Scalper macerator that introduced the technique of the self-sharpening, freely rotating circular blades mounted on an eccentric stroke parallel to the outer edge of a counter blade driven by a hydraulic motor.

The sharp edge of the circular blades moves overlapping the outer edge of the counter blade holes like a pair of scissors

Compressed against a counter blade coaxial to the blade holder and featuring eccentric orifices too, these circular blades are driven by the rotation of the blade holder and pivot in the opposite direction of the latter on their own axis.

The sharp edge of the circular blades moves overlapping the outer edge of the counter blade holes to chop the fibres or slurries.

The new Scalper

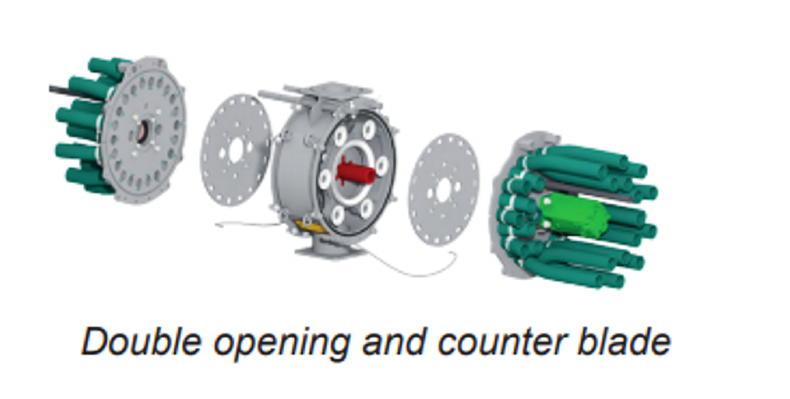

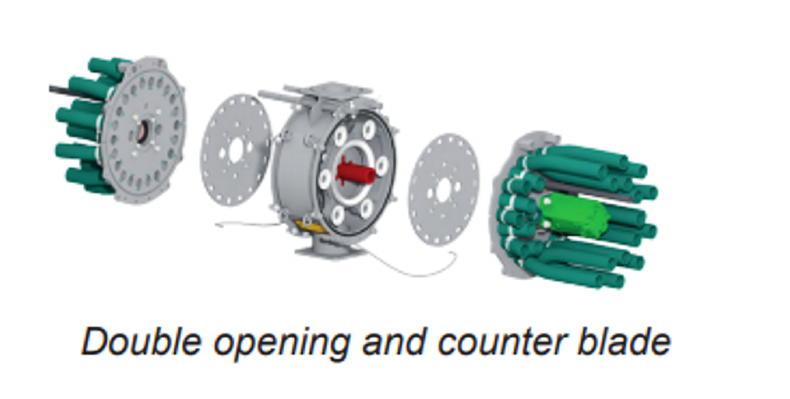

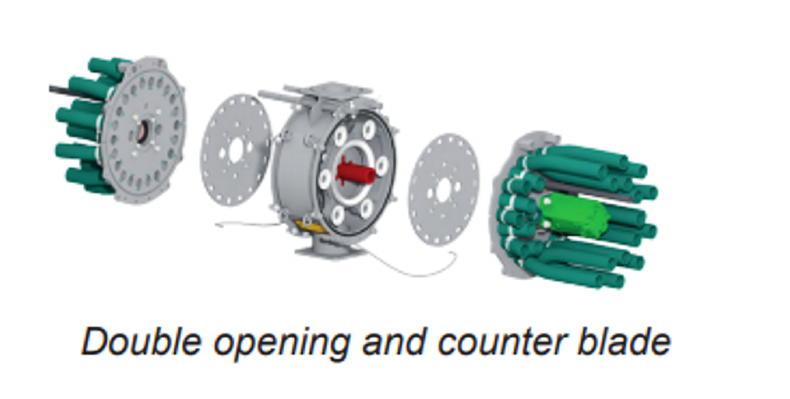

The new Scalper macerator keeps the original design as above, but Joskin says its doubling it to increase the flow capacity.

Joskin says it guarantees a greater

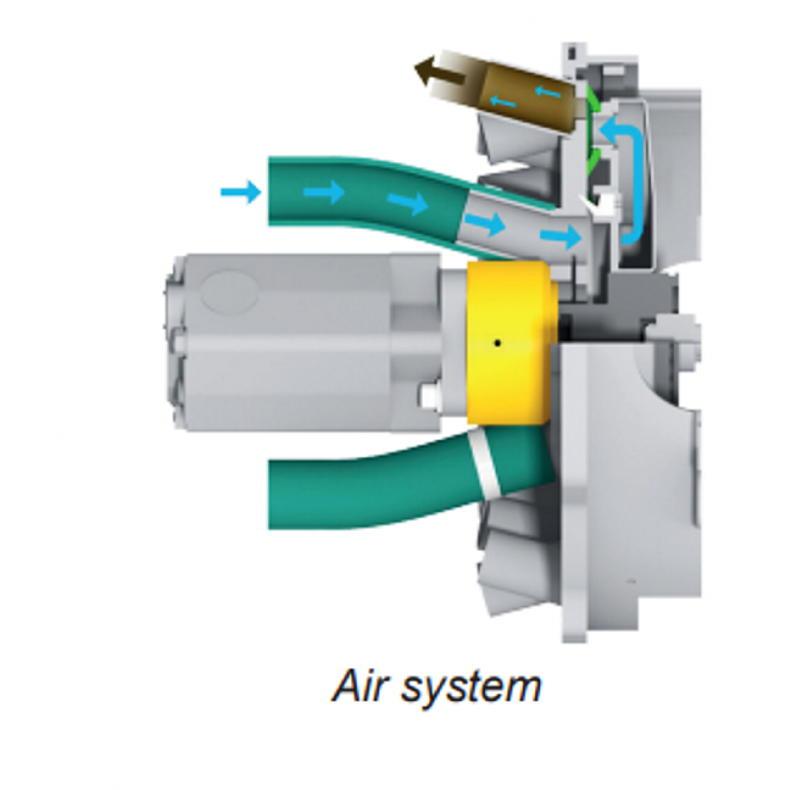

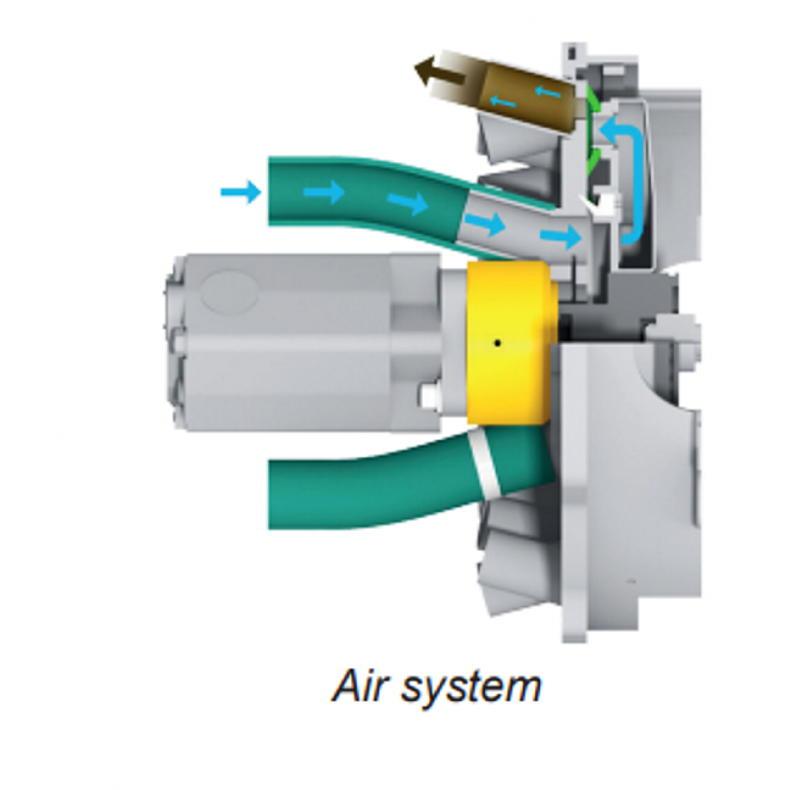

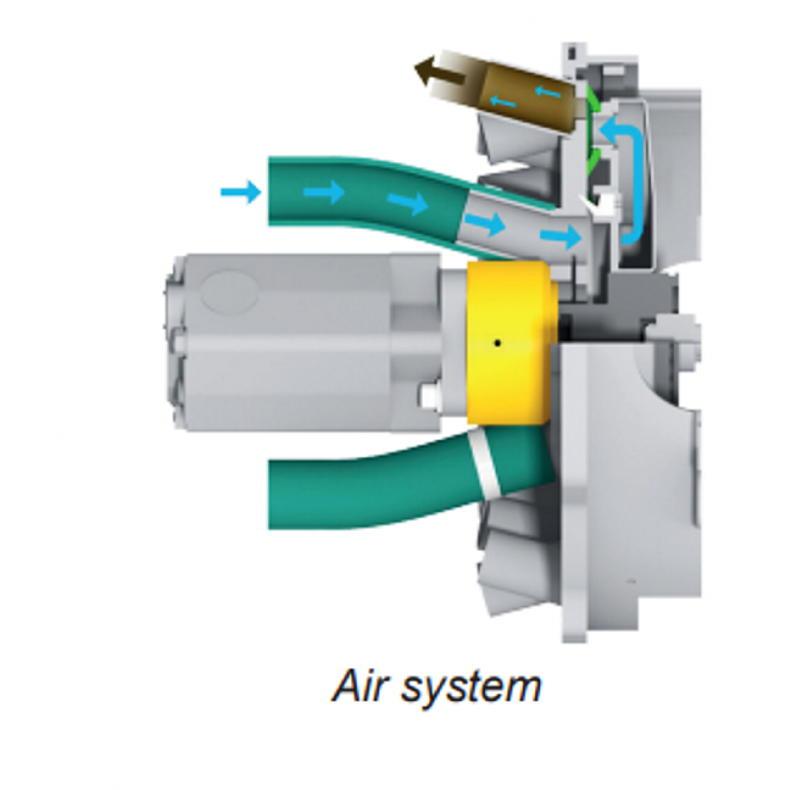

spreading uniformity thanks to a new air intake in the center of the knives.

Two blade holders, each with six blades, are compressed by a central spring on to the counter blades arranged on the two opening covers on either side of the macerator.

It says this double opening allows a much faster cleaning or replacement of the wear parts, with all blades accessible without having to remove the hoses. For cleaning, two openings allow for quick access to the inner mechanism.

It claims the new macerator cuts the fibres and foreign bodies at the entrance of the opening like a scissors, pinched between the circular blade and the outer edge of the opening and sheared off. It adds that this is repeated at least six times for each revolution of the blade holder.

It says spreading uniformity is improved thanks to new air intake in the centre of the knives. It adds that this system eliminates the pulsation effect that can be created by knives with diameters greater than the length of the distribution holes.

Counter blades

With its new macerator, Joskin is offering several types of counter blades. These are distinguished by the size of the distribution hole to allow different flow rates (m³/ha).

An overview of the macerator design.

It notes that the larger the hole size, the greater the spreading rate at equal speed. All counter blades are produced in Hardox steel for higher wear resistance.

The new macerator is supplied by five-inch hoses and will be fitted on Joskin’s Penditwist dribble bars, Pendislide trailing shoes and on its Solodisc XXL disc injectors.

Joskin has just taken the wraps off its latest Scalper macerator.

According to the Belgian manufacturer, the new version provides greater precision and versatility and can now be fitted to a wider range of implements in its range.

Joskin first patented the Scalper macerator in 1991.

It says it’s designed to work with cattle slurry, which is often obviously loaded with fibres and foreign bodies, that can cause irregularities in spreading and clog pipes.

How does it work?

Interestingly, Joskin claims that it was the Scalper macerator that introduced the technique of the self-sharpening, freely rotating circular blades mounted on an eccentric stroke parallel to the outer edge of a counter blade driven by a hydraulic motor.

The sharp edge of the circular blades moves overlapping the outer edge of the counter blade holes like a pair of scissors

Compressed against a counter blade coaxial to the blade holder and featuring eccentric orifices too, these circular blades are driven by the rotation of the blade holder and pivot in the opposite direction of the latter on their own axis.

The sharp edge of the circular blades moves overlapping the outer edge of the counter blade holes to chop the fibres or slurries.

The new Scalper

The new Scalper macerator keeps the original design as above, but Joskin says its doubling it to increase the flow capacity.

Joskin says it guarantees a greater

spreading uniformity thanks to a new air intake in the center of the knives.

Two blade holders, each with six blades, are compressed by a central spring on to the counter blades arranged on the two opening covers on either side of the macerator.

It says this double opening allows a much faster cleaning or replacement of the wear parts, with all blades accessible without having to remove the hoses. For cleaning, two openings allow for quick access to the inner mechanism.

It claims the new macerator cuts the fibres and foreign bodies at the entrance of the opening like a scissors, pinched between the circular blade and the outer edge of the opening and sheared off. It adds that this is repeated at least six times for each revolution of the blade holder.

It says spreading uniformity is improved thanks to new air intake in the centre of the knives. It adds that this system eliminates the pulsation effect that can be created by knives with diameters greater than the length of the distribution holes.

Counter blades

With its new macerator, Joskin is offering several types of counter blades. These are distinguished by the size of the distribution hole to allow different flow rates (m³/ha).

An overview of the macerator design.

It notes that the larger the hole size, the greater the spreading rate at equal speed. All counter blades are produced in Hardox steel for higher wear resistance.

The new macerator is supplied by five-inch hoses and will be fitted on Joskin’s Penditwist dribble bars, Pendislide trailing shoes and on its Solodisc XXL disc injectors.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: